Tom Ashley, Managing Director

For any business that produces goods for the consumer market, the importance of quality control (QC) cannot be overstated. Notwithstanding the considerable cost savings involved in handling returns, a well-planned QC process is a vital component in preserving your brand reputation. This is particularly important for our Fashion and Beauty clients, whose customers expect nothing short of perfection from their very high quality products.

In an ideal world, products would go straight from the manufacturer onto the warehouse shelves without any problems. Alas, it doesn’t always happen that way in the real world. Products arrive late, are coded incorrectly, poorly packaged and sometimes even damaged or faulty. It’s essential not only to catch these issues but also to have the facility to rectify them as quickly as possible.

How your warehouse can help

Your fulfilment partner can play two vital roles when it comes to quality control: firstly, as the last checkpoint before goods go out to your customers, it can be briefed to catch any quality issues; secondly, with the right skills and knowledge, it can put things right, saving time and money.

Having delivered high-quality fulfilment services for the Fashion and Beauty sector for many years now, quality checking and rework have become essential parts of our offering. We pride ourselves on knowing our clients’ products very well but we acknowledge that we can never know your products as well as you do – no fulfilment partner can and that’s important to bear in mind. That’s why we encourage our clients to work with us to enable us to carry out quality checking and rework to their high standards.

Pass on your knowledge

The more you can share knowledge with your fulfilment partner, the better they will be at managing your QC. Make time to impart all the knowledge you have, all the faults you’ve picked up on and all the tips you have to make things easier and, most importantly, faster. The faster an item can be quality checked the less it will cost and the more time you will have to sell it.

If you’re preparing to outsource for the first time, consider documenting out your current QC processes in advance. There will be some generic things to look out for but there may also be checks which are specific to a product. All this information will be helpful.

Samples save headaches

It also pays to have a robust sampling process, which includes any outer packaging and labeling. This will capture most issues before they have a chance to be blown up across an entire collection. It can certainly help to avoid real world problems like one we recently had to deal with.

We received 20,000 units of a client’s product into our warehouse but when we tried to scan the barcodes none of them were recognised by our system. Further investigation revealed that the supplier had added an extra digit to the barcode – an apparently tiny mistake with huge repercussions. It meant that none of the items could be scanned and, more serious still, the barcodes on the style sheets that had been shared with retailers were all wrong. Having caught the problem with our QC process, we assembled our rework team to produce and affix the correct barcodes, which was greatly appreciated by our client.

While we can add bags, barcodes etc at the warehouse, as a general rule it is always cheaper and quicker to have these jobs carried out (accurately!) at source. Not only does it hugely slow down the goods receipt process but it will generally be charged at a higher per unit rate.

Rework and kitting

Our rework and kitting teams offer valuable efficiencies for clients who sell a range of goods that are made up of shared components. For example, one of our clients is a watch brand whose customers can specify different details of the watch they want, eg strap designs. We are able to assemble orders on demand, giving our client greater flexibility on their stock holding.

We are able to offer this service to high-end clients because we work closely with them to gather the knowledge and skills we need. Our clients trust us to send out their products to their clients at the level of quality that is expected of their brand. That is a major responsibility and one that requires an investment in good people. But it’s a challenge that we are always happy to take on because our commitment to quality and our partnership approach are what set us apart.

Ensure Quality Control You Can Trust with ILG

The importance of efficient quality control cannot be overstated. Here at ILG, we ensure quality control to the highest level. Our willingness to fix problems and prioritise high-quality services is why some of the biggest fashion, beauty and wellbeing brands trust ILG. If you’re ready to outsource your fulfilment, enquire today.

Contact Us

More insights >

ILG Wins GDBA Environmental Culture Award!

ILG was awarded the Environmental Culture Award at the Gatwick Diamond Business Awards 2025!

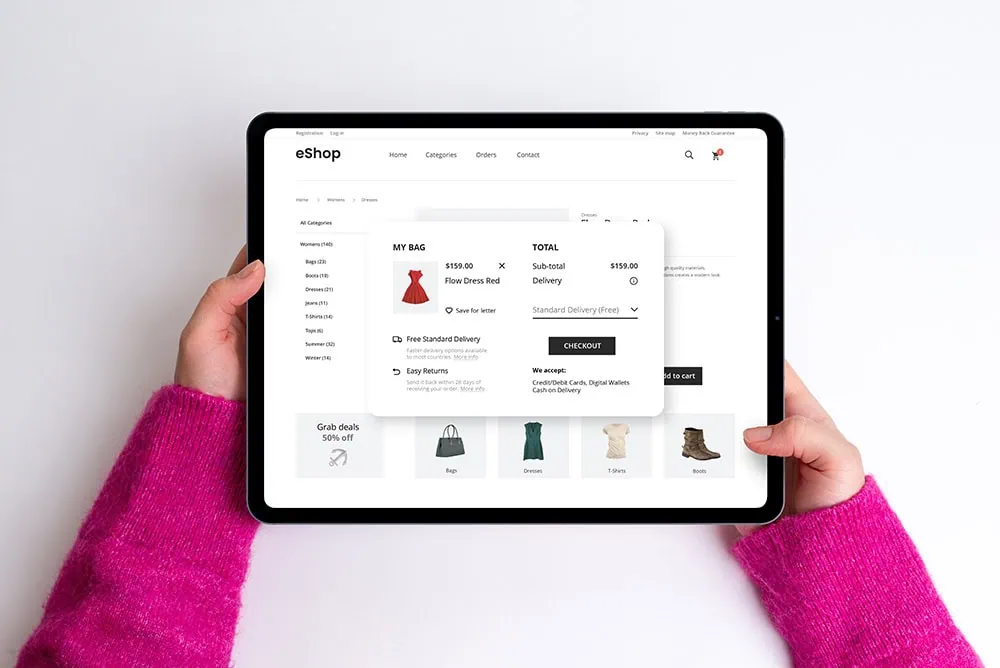

Battling E-Commerce Basket Abandonment in a Zero-Tolerance Era

In today’s volatile retail landscape, UK retailers are losing a staggering £34.4 billion annually to e-commerce basket abandonment. Find out how to tackle it here.